address:221 Fukang Industrial Park, Guanlan Renmin Road, Longhua District, Shenzhen

The phone:0755-81710691

phone:13925271184

-

Brief description of the main advantages of the welder which

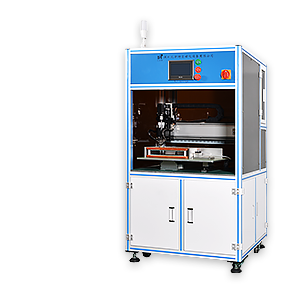

Butt welder also known as current welder or resistance bump welder. Utilizing the resistance between the contact surfaces of the two workpieces, instantaneously passing a low-voltage, high-current causes the contact surfaces of the two butt-joined metals to instantaneously heat to melt and fuse. To achieve the purpose of welding two metal together. 1, energy-saving. Radiator flash butt welding machine uses two 125KVA resistance welding transformer for power supply, pneumatic compression, upset, no hydraulic station. Compared with other other using two 315KVA single-phase AC resistance welding transformer And two power 18KVA hydraulic station welder, BT-136D automatic spot welder for 18650 batteries digital batteries, power batteries, mobile power standard production. 2, the direction of any spot welding spot design, two or four points 3, High welding precision Adopting PLC and imported stepping motor to control the flash process, can accurately set the amount of burn-in and burn-in speed, and control the welding current through the microcomputer resistance welding controller. Can be controlled within ± 0.2mm, easy follow-up of the chip welding. 4, automatic centering function to ensure that both ends of the pipe before the welding and two titles of the same pitch, so as to ensure the amount of both ends of the same amount of burning. 5, high welding efficiency due to the workpiece is compressed times the force cylinder, the reaction speed was significantly faster than the hydraulic cylinder. 6, Convenient operation and maintenance service. Because there is no hydraulic station, the debugging point of the product, the point of failure should be less, there will be no leakage phenomenon.

-

Spot welding machine daily operation and maintenance

1, First of all, before using the spot welder, the staff need to check whether the equipment of the spot welder is operating normally, run for a period of time after the power is on, and observe carefully. If there is no abnormality, the equipment functions normally.

-

Exchange the advantages and disadvantages of automatic spot welder

Determine the workpiece is welded black metal, the general election AC automatic spot welding. Because the AC spot welder adopts AC discharge welding, it is especially suitable for the material with larger resistance value. At the same time, AC spot welder can control all kinds of control methods by using single pulse, multi-pulse signal, cycle, time, voltage, current, Was the implementation of single-point workpiece, two-point continuous, automatic control, artificial control of welding. For tungsten, molybdenum, iron, nickel, stainless steel and other metal pieces, rods, silk materials welding. Its advantages are: 1. Comprehensive benefits better cost-effective 2. Welding conditions range 3. Welding circuit small and lightweight 4. Can be widely spot welding dissimilar metals. The disadvantage is: 1. Affected by the grid voltage fluctuations, AC automatic spot welding welding current fluctuations with the grid voltage fluctuations, thus affecting the consistency of welding. 2. AC welding spot welding discharge time is shortest is usually 1/2 or 0.01 seconds, not suitable for some high alloy special alloy welding.

-

Small frequency inverter spot welder with easy automation features

Small IF inverter spot welding without adding any solder, high efficiency, low cost. Easy to automate and so on. IF inverter spot welding using high-performance pneumatic components, the main shaft and the guide shaft are chrome round, the pressure transmitted is flexible and reliable, no phantom generated. Welding transformer secondary internal forced cooling, and the use of optimized design, high permeability materials, low load loss, power output, stable, long life.

-

IF frequency welder pressure refers to what

MF spot welding pressure, both the upper electrode and the lower electrode contact pressure value presented by the valve, there will be a general workpiece between the electrodes, today mainly introduces the pressure changes when the workpiece conditions. Now spot welding on the market generally adopt a single pressure, and set a fixed pressure, depending on the importance of bow and arrow, and the need to do welding flaw detection, advanced solder joints need to have a certain pressure curve, such as welding aluminum and aluminum Saddle-shaped pressure curve when the alloy sheet, but this need rarely on the market, of course, because the cost is too high, the general spot welding welding, the pressure between the two workpieces and the electrode has a great relationship, when the upper and lower electrode Squeeze together, the current flows through the workpiece, the metal sheet melting to form solder joints, most people think that the pressure required by the sheet is small, the amount of pressure on the plate is large, in fact, the actual application, the pressure of the metal sheet welding often than usual A little bigger, so when the plate is melted, it can timely and effectively overcome the deformation of the wood, the back of the welding is good, and the so-called non-spot welding; when the welding plate, the pressure does not need too much, should be a little smaller than usual A little because the back of the deformation is not dependent on the pressure, small pressure spatter, forming a good nugget.