MF spot welding pressure, both the upper electrode and the lower electrode contact pressure value presented by the valve, there will be a general workpiece between the electrodes, today mainly introduces the pressure changes when the workpiece conditions.

Now spot welding on the market generally adopt a single pressure, and set a fixed pressure, depending on the importance of bow and arrow, and the need to do welding flaw detection, advanced solder joints need to have a certain pressure curve, such as welding aluminum and aluminum Saddle-shaped pressure curve when the alloy sheet, but this need rarely on the market, of course, because the cost is too high, the general spot welding welding, the pressure between the two workpieces and the electrode has a great relationship, when the upper and lower electrode Squeeze together, the current flows through the workpiece, the metal sheet melting to form solder joints, most people think that the pressure required by the sheet is small, the amount of pressure on the plate is large, in fact, the actual application, the pressure of the metal sheet welding often than usual A little bigger, so when the plate is melted, it can timely and effectively overcome the deformation of the wood, the back of the welding is good, and the so-called non-spot welding; when the welding plate, the pressure does not need too much, should be a little smaller than usual A little because the back of the deformation is not dependent on the pressure, small pressure spatter, forming a good nugget.

News

- Brief description of the main advantages of the welder which

- Spot welding machine daily operation and maintenance

- Exchange the advantages and disadvantages of automatic spot welder

- Small frequency inverter spot welder with easy automation features

- IF frequency welder pressure refers to what

- Automatic spot welding main components and features

Product

-

BT-100V-20C-200F BATTERY PACK PERFORMANCE TESTER

BT-100V-20C-200F BATTERY PACK PERFORMANCE TESTER

2021-04-09

-

BT-2113B ENERGY-STORAGE POWER BATTERY PACK SEMI AUTOMATIC PRODUCTION LINE

BT-2113B ENERGY-STORAGE POWER BATTERY PACK SEMI AUTOMATIC PRODUCTION LINE

2021-04-09

-

BT-450 INSULATING PAPER PASTING MACHINE

BT-450 INSULATING PAPER PASTING MACHINE

2021-04-09

-

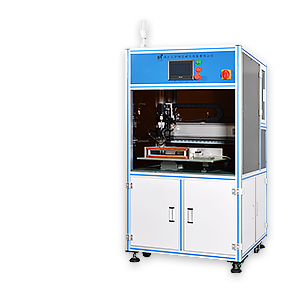

BT-850B-10000A TRANSISTOR DOUBLE SIDED AUTOMATIC SPOT WELDING MACHINE

BT-850B-10000A TRANSISTOR DOUBLE SIDED AUTOMATIC SPOT WELDING MACHINE

2021-04-02

-

BT-960-960XZ Single Side Automatic Spot Welder

BT-960-960XZ Single Side Automatic Spot Welder

2021-04-01

Telephone:0755-81710691

Fax:

Mailbox:z609665418@163.com

Address:221 Fukang Industrial Park, Guanlan Renmin Road, Longhua District, Shenzhen

粤ICP备14041565号